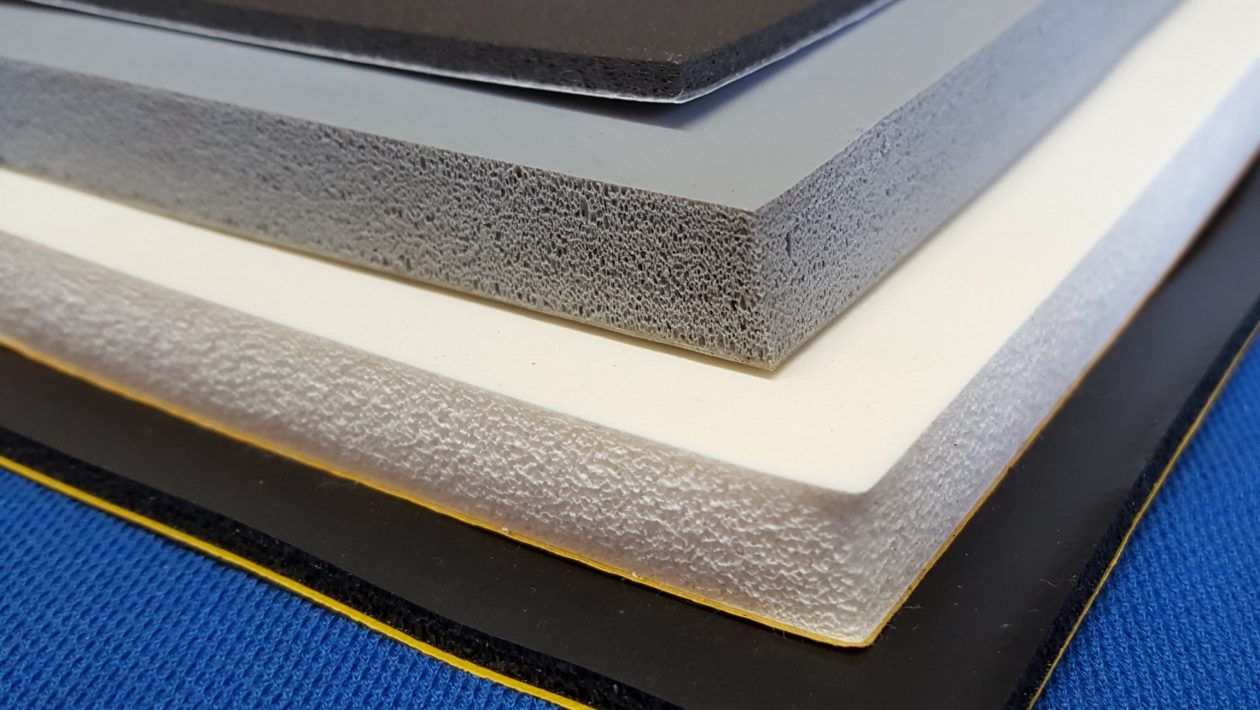

Silicone sponge is a synthetic elastomer with unique physical properties. Most commercially available products are made from gum-based polydimethylsiloxane (PDMS). The silicone sponge sheets offer several benefits, which is one of the reasons for its multiple applications.

Silicone Sponge Applications

A closed-cell Silicone Sponge Sheets can be fabricated into several products. The end uses of these products are areas that require a material that is quality-consistent, dependable, and deliver outstanding performance.

Silicone sponge also meets critical safety standards of industries in hard-working environments, which increase its potential uses in different sectors like automotive construction, food, and beverage, oil and gas, mass transit, HVAC, and LED lighting.

Environmental Shields

The primary purpose of EMI shielding is to prevent radio interference(RFI) and electromagnetic interference(EMI) from impacting sensitive electronics. Silicone sponge is widely used as EMI/RFI gasket materials. These EMI shielding gaskets/Electrically conductive gaskets are applied to doors, covers, and penetrations to restrict or prevent electromagnetic emissions that can interfere with electronics.

Automotive Seals and Vibration Damping Pads

Silicone sponge is primarily used to make seals and vibration damping pads in the automotive industry. The closed-cell structure of the silicone sponge allows for good water sealing. It has a wide operating temperature range of -100°F to 500°F.

Silicone has a variety of available mechanical properties that are useful in the automotive industry. These mechanical properties are constant between–50 to +200°C. Also, it has excellent resistance to weathering and UV radiation. Other important properties include excellent water repellency, low moisture absorption, and resistance to many chemicals.

Pads made from silicone sponge sheets are a good fit for mechanical shock absorption. Silicone sponge has less mass and considered ideal vibration dampening in small and medium-sized devices. They prove good alternatives to solid materials that are too firm for small accessories.

Medical Equipment

Silicone sponge is also used in many components of medical diagnostic devices. These devices often require pads and gaskets with unique properties. It is known for properties like inertness, longevity, and resilience. Also, it meets various requirements of EMI shielding, ESD protection, and electrical conductivity.

Medical devices often require specialty foam gaskets for filters and displays. Silicone foam sheets can be easily fabricated into solid gaskets and cushioning pads. These gaskets and cushioning pads are specified to reduce noise in equipment designed to use near patients.

Access Panels

The access panels and doors of a rail car use silicone sheets due to their resilience and durability. It is used to seal panels, and doors infrequently operated, such as maintenance closets. Silicone sponge also has applications for doors and electrical panels in high-temperature areas.

It is ideal for such applications as the material meets FRA requirements for smoke, flame, and toxicity. Silicone sponge is also used in battery cover gaskets, which require soft material. Its ability to withstand high temperatures and makes it ideal for use in electrical panels and batteries.

Adhesive Tapes

Silicone sponge adhesive tapes permit substantial savings. They simplify production, eliminate the high cost of bonding, and are easy to apply. These adhesive tapes can withstand the same high temperatures as silicone sponge with a temperature range of -40°F to + 300°F.

Thus, you can see the unique properties of silicone sponge make it ideal for many applications in different industries.